Large Capacity Liquid to Liquid Thermal Shock Chamber

A lineup of large-capacity Liquid to Liquid Thermal Shock Chambers

Today, the automotive industry accelerates electronic multi-functions. According to this trend, safety standards such as ISO26262 and IEC61508 require high environmental stress that is generated by thermal shock chambers for higher reliability of vehicle equipments.

Three large-capacity chambers have been added to the TSB series of Liquid to Liquid Thermal Shock Chambers.

Compared to the air to air thermal shock type, the liquid to liquid thermal shock type applies higher stress on the specimen, and shortens a test time.

In addition, the weight load has been increased in accordance with the larger specimen basket, thereby enabling support of large specimens.

The in-vehicle inverter can be evaluated as a fully assembled product or with components mounted; it makes it possible test specimen while current is carried. As a result, this model offers an environment similar to actual conditions in the reproduction of heat stress during failure mode analysis such as of BGA mounting.

Large-capacity test area

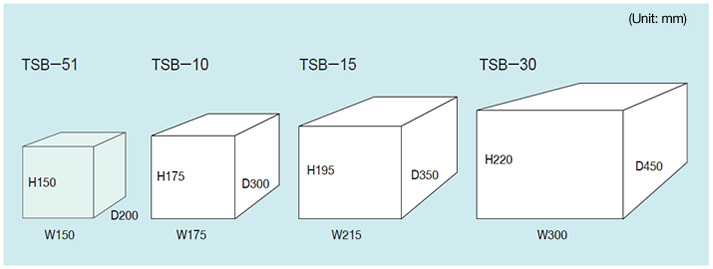

It is available from three test area capacities: approximately 10 liters, 15 liters, and 30 liters.

Various mechanisms to greatly reduce consumption of brine

To reduce brine consumption, the airtightness of the test area has been increased to prevent vapor leaks and evaporation has been prevented.There are also other mechanisms to recycle brine after separating water by the filter for. The Galden® fluid hardly leaks. For support status of silicon oil and Fluorinert, please contact our sales representatives.

Smooth specimen transfer

An air cylinder reduces vibration to the specimen. A new drivel mechanism, when inserting the specimen into the water bath, is being used to control excess stress to the specimen during transferred between the hot chamber and cold chamber.

TSB series common operability

Basic control method is common by using the same interactive touch panel instrumentation as that of the standard Liquid to Liquid Thermal Shock Chamber.

TSB-10

TSB-15

TSB-30

Main specifications

Model TSB-10 TSB-15 TSB-30 Method Two-chamber method using specimen basket transfer Hot chamber temperature range +60 to +150°C Cold chamber temperature range -65 to 0°C Specimen transfer time (between hot chamber and cold chamber) 15 seconds or less 20 seconds or less 25 seconds or less Specimen basket dimensions (mm) W175×H175×D300 W215×H195×D350 W300×H220×D450 Specimen basket load capacity (equally distributed load) 5kg 10kg 10kg Outside dimensions (mm) W1410×H2100×D1520 W1610×H2310×D1520 W2871×H2185×D1846 Weight Approx. 1,100kg Approx. 1,150kg Approx. 2,500kg Power supply voltage 200 V AC, 3 ohm, 3W, 50/60 Hz (Supporting any power supply voltage as an option) Maximum current value 47A 132A Cooling water volume (at 25°C cooling water) Air cooled 5820L/hr Cooling water volume (at 30°C cooling water) Air cooled 11700L/hr Piping connection port diameter Air cooled 50A

Test area (specimen basket dimensions)