Espec laboratory vietnam - Thermal shock test service

2024-09-20Product

|

ESPEC VIETNAM’S LABORATORY – THERMAL SHOCK TEST SERVICE

1.What is thermal shock test? |

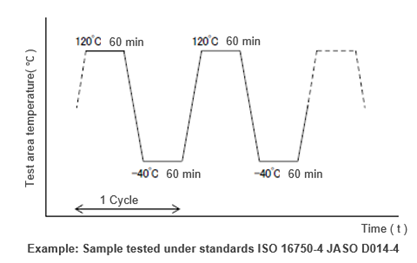

| Thermal shock, that is, high and low temperature shock test, is to expose the test sample to the continuous alternating environment of high temperature and low temperature, so that test's sample experiences a sharp change in temperature in a short period of time, to assess the adaptability of the product to the sharp change of the surrounding environment temperature |

|

2.Testing Purposes. |

|

①. In the research and development stage, the thermal shock test can be used to find the design and process defects of the product. ②. In the stage of product finalization or design appraisal and mass production, the thermal shock test is used to verify the adaptability of the product to the temperature shock environment and provide a basis for design finalization and mass production acceptance decisions. ③. When used as an environmental stress screening application, the purpose of thermal shock is to eliminate early failures of products. |

3.Scope of Application. |

|

Thermal shocks test is mainly aimed at Semiconductor, electronic products, mechanical parts, and auto parts. |

|

Specific examples of thermal shock: |

|

①. Movement between the warm indoors and cold outdoors |

|

②. When the device is exposed to rain or immersed in cold water and suddenly cool down |

|

③. A sudden temperature rise of parts due to power ON and OFF |

|

④.Rapid ascent and descent of the aircraft |

|

⑤.Find solder cracks caused by the poor manufacturing process |

4.Compatible test standards. |

|

Major Test Items in Reliability: |

|

IEC 60749-25 |

Semiconductor devices – Temperature cycling |

|

IEC 60068-2-14 Na |

Environmental testing – Change of temperature |

|

IEC 61747-5 |

Liquid crystal and solid-state display devices – Environmental, endurance and mechanical test methods |

|

MIL-STD-883 |

Military standard, microcircuits, test standards |

|

IPC-TM-650 2.6.6 |

Temperature cycling, printed wiring board |

|

SAE J1879 |

Handbook for robustness validation of semiconductor devices in automotive applications |

|

JASO-D902 |

Durability testing methods for automotive electronic equipment |

|

EIAJ ED-4701 |

Environmental and endurance test methods for semiconductor devices. (General) |

|

EIAJ ED-4702 |

Mechanical stress test methods for semiconductor surface mounting devices |

|

EIAJ ED-7407 |

Environmental and endurance test methods for CSP, BGA package on mounting condition |

5.Espec's laboratory in Vietnam. |

|

We have TSE-12-A series, which is specialized for thermal shock testing with small and small quantity of samples, capable of testing JIS60068-2-14, MIL-STD-883, JACO-D902, etc. |

|

|

|

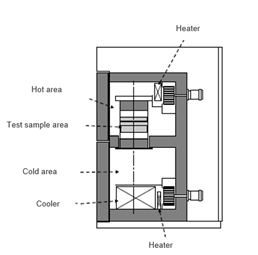

The sample will be placed in the test tray and brought into the test area. |

|

The low temperature chamber and the high temperature chamber are both connected through a test area. By moving this test area up and down, the sample will be switched between hot and cold zones in a short period of time. |

|

In addition to the above standards, we can also conduct tests according to customer-specific test conditions. |

|

If you have any questions, please don't hesitate to contact us.

|